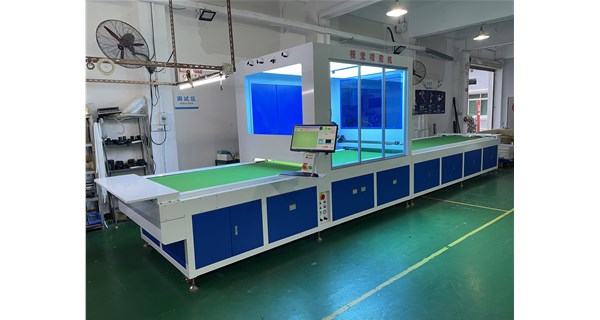

Julong Machinery's Vision-Based Glue Spraying Machine: Precise Glue Control with "Eyes," Empowering New Efficiency in Automated Production

A New Revolution in Glue Spraying: A Leap from "Experience-Based Operation" to "Visual Precision"

In industries such as electronics assembly, automotive parts, packaging printing, and Handbags and luggage, glue spraying is a crucial step in ensuring strong adhesion and waterproof sealing of products. Traditional manual glue spraying relies on operational experience, easily leading to uneven glue application, misalignment, and glue leakage, affecting product quality, wasting glue, and reducing production efficiency. Dongguan Julong Machinery Co., Ltd., keeping pace with the trend of automated production, has independently developed and produced vision-based glue spraying machines. Utilizing the core technology of "machine vision + intelligent glue control," it achieves precision, automation, and high efficiency in the glue spraying process, becoming a powerful tool for enterprises to enhance their production competitiveness.

Core Technology: A Vision "Insight," Bringing Glue Spraying Errors Close to Zero

The core advantage of Julong Machinery's vision-based glue spraying machine lies in its high-precision visual positioning system, combined with intelligent algorithms and precision actuators, elevating glue spraying accuracy to a new level and completely solving the pain points of traditional glue spraying.

1. High-Definition Visual Positioning, Precise and Deviation-Free Capture

Equipped with a 20-megapixel industrial camera and a high-magnification optical lens, combined with an LED ring light source, it can clearly capture minute features on the workpiece surface, achieving a positioning accuracy of 0.01mm. The vision system automatically identifies the workpiece contour, reference points, and adhesive spraying path. Even with slight placement deviations, it can automatically correct them in real time, controlling the positioning error within ±0.02mm, far exceeding the ±0.5mm error standard of manual adhesive spraying. This fully meets the high-precision adhesive spraying requirements of precision electronic components, miniature medical devices, and other applications.

2. Intelligent Path Planning, Precise and Controllable Adhesive Volume and Speed

Equipped with a self-developed vision-based adhesive control system, it supports three path planning modes: automatic import of CAD drawings, offline programming, and online teaching. The system can intelligently set the adhesive volume (adjustable in 0.001ml increments), spraying speed (infinitely adjustable from 1-500mm/s), and dispensing frequency according to the workpiece's adhesive spraying requirements. It achieves smooth transitions and uniform adhesive dispensing for complex paths such as arcs, broken lines, and irregular curves. For example, in mobile phone button glue spraying, the glue line width can be precisely controlled to 0.1mm, preventing glue overflow and contamination of button contacts.

3. Real-time detection and feedback significantly reduces defect rates.

The vision system not only handles positioning but also performs real-time quality inspection. During the glue spraying process, the camera simultaneously captures the glue line shape, and algorithms automatically determine whether there are problems such as glue leakage, glue breakage, or abnormal glue amount. Once a defect is detected, an alarm is immediately triggered and production is paused. The location and type of the defect are recorded for subsequent process optimization. Products processed by Julong vision glue spraying machines have a glue pass rate that increases from 85% with traditional manual methods to over 99.5%, significantly reducing rework costs.

Core Equipment Advantages: A Versatile Automated Solution Adaptable to Diverse Scenarios

In addition to precise visual positioning, Julong Machinery's vision glue spraying machines demonstrate strong competitiveness in stability, compatibility, and intelligence, flexibly adapting to the production needs of different industries.

1. Highly Stable Structure, Uninterrupted Continuous Production

Utilizing a heavy-duty cast iron body and linear guide slide, coupled with a servo drive system, the machine operates smoothly without vibration. Under 24-hour continuous production conditions, the equipment failure rate is less than 0.5%. The glue spraying valve uses an imported high-speed solenoid valve with a response speed of 0.01s, supporting multiple glue spraying modes such as dispensing, line dispensing, and surface dispensing. It has a wide range of adhesive viscosities, stably conveying everything from low-viscosity silicone to high-viscosity hot melt adhesives.

2. Superior Compatibility, One Machine Adapts to Multiple Workpiece Types

The machine's worktable supports workpiece size adjustment from 50-500mm and is equipped with quickly changeable tooling fixtures. For workpieces of different shapes and materials (metal, plastic, glass, ceramics, etc.), changeover and debugging can be completed in just 5 minutes. It is also compatible with various types of adhesives, including single-component and two-component adhesives, and supports multiple glue dispensing methods such as pressure tanks and syringes, meeting the diverse needs of industries such as electronics, automotive, and packaging.

3. Intelligent Linkage Control, Integrated into Automated Production Lines

Supports integration with MES production management systems, AGV handling robots, conveyor belts, and other automated equipment to achieve fully unmanned operation throughout the entire process of "loading-positioning-glue spraying-inspection-unloading." Equipped with a 7-inch touchscreen display, the user interface is simple and intuitive, allowing workers to operate the machine after simple training. Equipment operation data can be uploaded to the cloud in real time, supporting remote monitoring and fault diagnosis, facilitating production management and efficiency analysis for enterprises.

4. Energy Saving and Consumption Reduction, Lowering Overall Production Costs

Precise glue dosage control increases glue utilization from 60% to over 95% compared to manual glue spraying, saving 30% on glue procurement costs monthly. Automated production reduces labor input by 80%, avoiding efficiency fluctuations associated with manual operation. The equipment's energy consumption is 20% lower than traditional semi-automatic glue spraying machines, resulting in a significant reduction in overall production costs for enterprises in the long term.

Industry Applications: Full-Scenario Coverage, Precise Adhesive Spraying Empowers All Industries

Leveraging its core advantages of precision, efficiency, and stability, Julong Machinery's vision-based adhesive spraying machine breaks down industry barriers and has deeply served dozens of manufacturing sectors, including packaging, automotive, home furnishing, and electronics, becoming the preferred equipment for automation upgrades across various industries.

1. Electronics & Digital Industry: Micro-Precision Adhesive Spraying Protects Product Performance

Suitable for scenarios such as mobile phone case bonding and speaker sealing and waterproofing. For the curved surfaces and opening positions of mobile phone cases, it can achieve 0.1mm-level adhesive line control, avoiding excess adhesive affecting the appearance; for precise adhesive spraying at speaker seams, it improves sound quality and sealing while preventing adhesive penetration and damage to internal components, helping electronic products enhance their quality competitiveness.

2. Automotive Interior Industry: Exquisite Adhesive Spraying Creates a High-End Driving Experience

Focusing on the refined adhesive spraying needs of automotive interior parts, it is suitable for core processes such as center console panel and leather bonding, door panel soft-pack encapsulation, seat stitching reinforcement, and interior ambient lighting installation. For interior trim surfaces with curved surfaces, irregular shapes, and stitching textures, the vision system can accurately identify bonding boundaries with a 0.02mm positioning accuracy to prevent exposed adhesive lines from affecting aesthetics. During the adhesive spraying process, intelligent control of the adhesive amount ensures a tight, bubble-free bond between the leather and the substrate while preventing adhesive penetration and contamination of the interior fabrics. The treated interior parts are resistant to high and low temperatures (-40℃ to 120℃), resistant to high-frequency vibration, and the adhesive layer is odorless, meeting automotive interior VOC environmental standards, helping automakers create high-end, durable driving and riding spaces.

3. Packaging and Printing Industry: Customized Adhesive Spraying Enhances Packaging Quality

Comprehensive coverage for gift boxes, eyeglass cases, wine boxes, notebook covers, label positioning, and other packaging scenarios. For gift boxes with hot stamping edges and irregular corners, it can precisely match the adhesive spraying path to avoid adhesive stains contaminating the printed pattern; it provides a uniform adhesive layer for the bonding of the inner lining and outer shell of eyeglass cases, ensuring smooth opening and closing without delamination; in the production of wine boxes and notebook covers, it supports various adhesive types such as matte adhesive and glossy adhesive to meet different packaging texture requirements, and is suitable for mass production and small-batch customization.

4. Sports Equipment and Protective Gear Industry

It is suitable for fabric bonding of sports knee pads, elbow pads, wrist guards, etc., and for the spraying adhesive process of equipment such as yoga mats, fitness gloves, and sports backpacks. For commonly used elastic fabrics and sponge padding layers in protective gear, the vision system can accurately identify splicing boundaries and intelligently adjust the amount and pressure of adhesive to prevent glue penetration that could affect fabric elasticity or cause surface hardening. In the bonding of anti-slip layers on yoga mats, it achieves large-area, uniform adhesive spraying, ensuring the anti-slip layer is firmly attached and does not detach. For the anti-slip texture of the palm on fitness gloves, it can precisely control the size and distribution of adhesive dots, improving comfort and grip, meeting the durability and safety requirements of sports equipment.

Dongguan Julong Machinery Co., Ltd. is an automation equipment enterprise integrating R&D, production, sales, and service. Focusing on adhesive spraying equipment for over 10 years, it boasts a core R&D team composed of experts in mechanical design, software algorithms, and automation control. The company has established a standardized production workshop and a comprehensive quality inspection system. Each vision-based adhesive spraying machine undergoes 100 hours of continuous operation testing, precision calibration, and safety checks to ensure stable and reliable quality before leaving the factory.

To meet the diverse needs of clients across various industries, Julong Machinery offers one-on-one customized services. From equipment selection and solution design to installation, commissioning, and personnel training, dedicated personnel provide full support throughout the process. We also offer 24-hour after-sales response and lifetime technical support, ensuring worry-free automation upgrades for your business.

Consult and Customize, Unlock a New Era of Precision Glue Spraying

Whether you need to improve glue spraying accuracy, reduce production costs, or plan to build a fully automated glue spraying production line, Julong Machinery can help you achieve a dual improvement in production efficiency and product quality with our professional vision-based glue spraying equipment and customized solutions.

- Previous:Application of Leather Automatic Visual Spray Adhesive Machine in Automotive Interior Production

- Next:Already the last article